New Regulations on Septicity Control in Section 106 Applications for Main Sewer Connections

Water companies are implementing new regulations concerning section 106 applications for connecting to main sewers, particularly focusing on addressing the issue of septicity. But what exactly is septicity, and why is it garnering attention from regulatory bodies and water utilities?

What is Septicity?

Septicity refers to a condition prevalent in foul pumping stations and rising mains, where bacteria present in foul sewage consume oxygen from compounds in the absence of free oxygen. This process often leads to the formation of hydrogen sulfide gas (H2S), resulting in various detrimental effects:

1. Unpleasant Odors: The characteristic 'bad egg' smell associated with hydrogen sulfide can lead to customer complaints and nuisance issues.

2. Health Hazards: Hydrogen sulfide poses a lethal gas hazard, especially during man entry into chambers.

3. Corrosive Effects: When hydrogen sulfide reacts with moisture, it forms sulfuric acid, which corrodes pipeline linings, concrete chambers, and electrical fittings.

To address these concerns, water companies are enforcing regulations outlined in the Water Industry Act 1991, particularly Section 111a, which aims to protect the sewerage system from the adverse effects of septicity.

Complying with the New Septicity Regulations: Steps to Follow

Some water companies are implementing a structured process for section 106 applications to connect to main sewers. Here's what applicants need to do:

1. Application Submission: Complete the septicity form provided by the water company and submit it to the designated authority.

2. Review Process: The water company will review the submitted data to assess the risk of septicity associated with the proposed pumping station or rising main.

3. Approval or Advice: Based on the review, if there is little or no risk of septicity, construction can proceed as planned. However, if there's a risk of septicity, the water company will provide advice on how to mitigate the risk effectively.

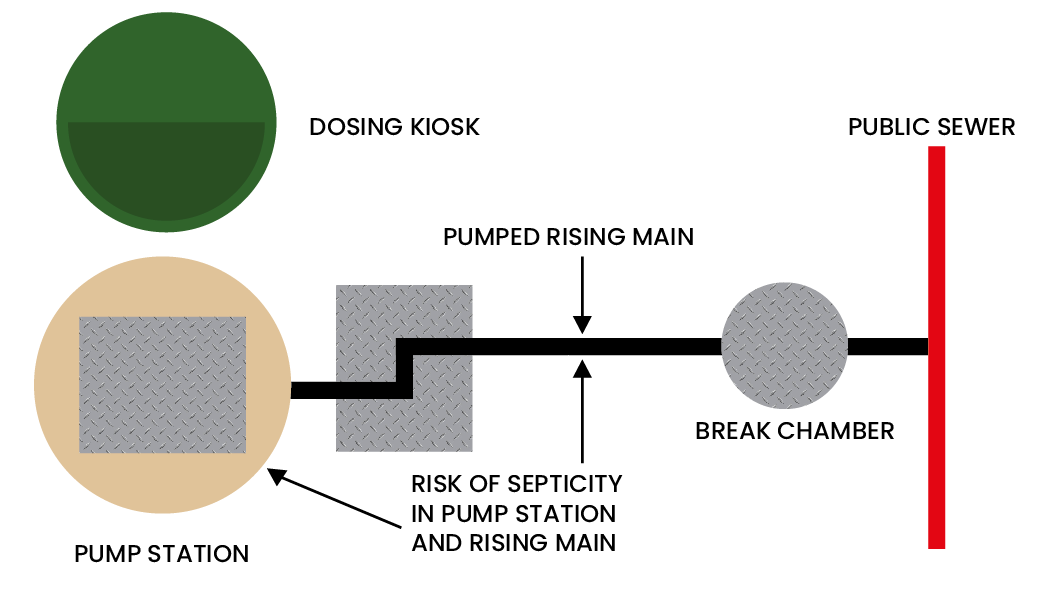

Pumping Station Septicity Control: Chemical Dosing Kiosk

One of the effective strategies for mitigating septicity risks is through chemical dosing. Water companies like Severn Trent employ predictive modeling to determine the likelihood of septicity occurrence. If septicity is identified as a concern, applicants may need to consider incorporating chemical dosing into their infrastructure design. The options for chemical dosing include:

Permanent Dosing: Installation of a dosing unit meeting specific design standards, including reinforced pads, fencing, and provision for eye wash stations.

Provision for Future Dosing: Temporary installations with provisions for future upgrades as per site requirements.

Temporary Dosing: Temporary or hired dosing units for construction phases, with or without provisions for future use.

Additional Costs

While there are often no fees for the regulatory review process, applicants will bear the costs associated with implementing recommended measures, including supplying and installing equipment and chemicals.