How often should a Klargester be serviced?

Klargester manufacture a number of Sewage Treatment Systems, such as the BioDisc, BioFicient and BioTec range, all of which require servicing in line with standard and extended warranty conditions. In addition, if you have a permit to discharge into a stream or ditch you will be legally required to keep a management record of when your system was emptied and serviced.

Each system has specific manufacturers guideline which specify when you need to have a service and get the system emptied. Most domestic sewage treatment systems up to 12 person such as the Klargester BioDisc BA/BB/BA-X require annual servicing and it is recommended to check the operation of your motor/gearbox and bearings every 6 months. Regular maintenance of a Klargester BioDisc sewage treatment plant is vital for its long term continued performance. Failure to have your treatment system serviced can result in expensive repairs and potential pollution into the environment. Commercial BioDiscs can often be fitted with loss of rotation alarms and dosing systems to maintain performance. These need regular checking to ensure correct functionality.

Direct Drainage has over 25 years of experience in supplying and maintaining Klargester sewage treatment systems. Our engineers are able to service and maintain every Klargester model and carry a full stock of spare parts that are essential for keeping a Klargester Sewage Tank at its peak performance.

Call us now for serviceable Klargester spare parts or to book a service on 01388 537 050 or browse our collections.

It is worth mentioning that we highly recommend the Klargester BioDisc as a Sewage Treatment solution. The system itself is among the most reliable on the market. However, with anything mechanical things can sometimes go wrong. In the event of a breakdown, Klargester tanks have a control panel that immediately identifies the fault so you can get it fixed as fast as possible.

Klargester BioDisc Sewage Treatment Systems bought prior to 2022 will have a Klargester Green Control Panel, while newer systems are supplied with a white Darcy control panel. The Klargester green control panel triggers a low voltage beacon to indicate any fault on the system. See below fault codes.

Klargester flashing light fault codes.

| CODE | FAULT CONDITION | FUSE | Amp |

| F1 | No Power to the unit | Custom Fuse box | N/A |

| F2 | The blower pressure has failed (PPFDS kit required) | N/A | N/A |

| F3 | The high level alarm has activated (where fitted) | N/A | N/A |

| F4 | The fuse box to the blower/motor has failed | F3 | 3.15 |

| F5 | The fuse to the discharge pump (where fitted) has failed | F1 | 5.0 |

| F6 | The fuse to the chemical dosing pump has failed | F4 | 0.25 |

| F7 | The fuse to the recirculation pump has failed | F2 | 5.0 |

| F8 | The loss of rotation alarm has been activated | N/A | N/A |

| -- | The unit has had a fault which has now corrected itself | N/A | N/A |

If your Klargester system is serviced by a Klargester approved servicing engineer such as RA Dalton then they will be able to attend site to rectify the issue quickly. Servicing engineers check a number of components at each servicing visit, see below checks that should be made on a Klargester BioDisc system on regular intervals for general wear and tear, signs of misuse or any issues that would be covered by Klargester warranty.

- Motor/Gearbox

- Drive Chain

- Belt Drive

- Bottom Sprocket

- Bearings

- Loss of Rotation (LOR)

- High Level Float

- Integrated Pump System (IPS)

- Pump Function

- Grease and Fat build up

- Holding Chamber

- Air Lift

- Sludge Return Pump

- Centre Couplings

- Disc Conditions

- Bucket Operations

- Check tichtness of U bolts & Clamps

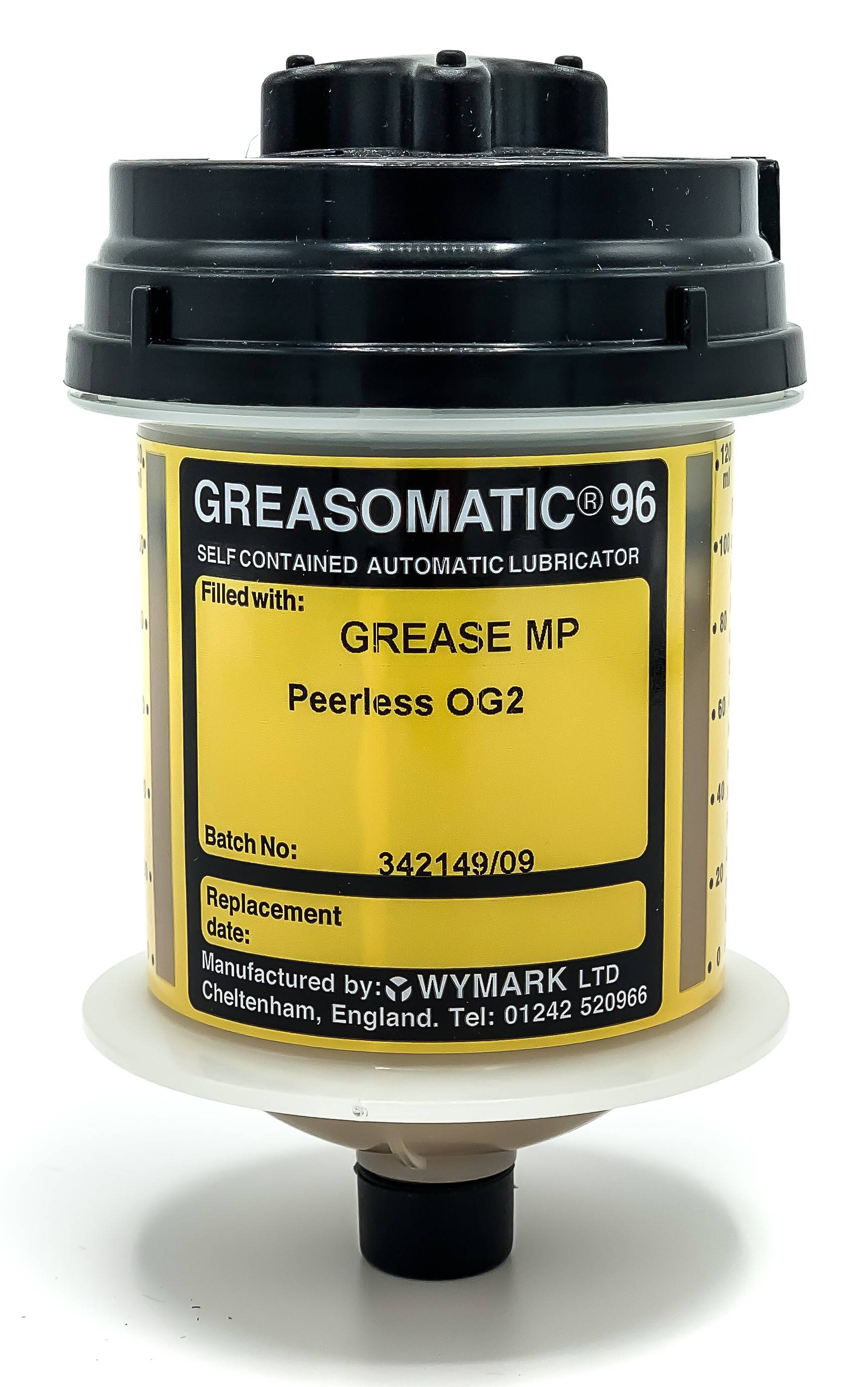

- Grease Cartridges (Greasomatics)

- Condition of Covers

- Humus Sludge Zone

- Sanitary Products present in system

- Overall plant performance

- BioDisc Alarm / Buzzer / Flashing Light

- Chemical Dosing Pump

- Condition of Kiosk

If you have a problem with your Klargester BioDisc or other Klargester Tank, the Klargester Flashing Light will flash. If the light is solid, this indicates there is a problem with the beacon itself. We supply a huge range of klargester spares providing drainage direct to your door for any problem.